RPI Step Motor controller - Viktor Mihalovic

Contents

Project Overview:

The primary goal of the RPI Step Motor Controller project is to automate the process of controlling the height of the Oree R-t model laser arm for laser marking in production. This automation involves automatically scanning a product's serial number, retrieving information from a database, and adjusting the height of the laser arm accordingly. This project was focused on part to manage height of laser arm

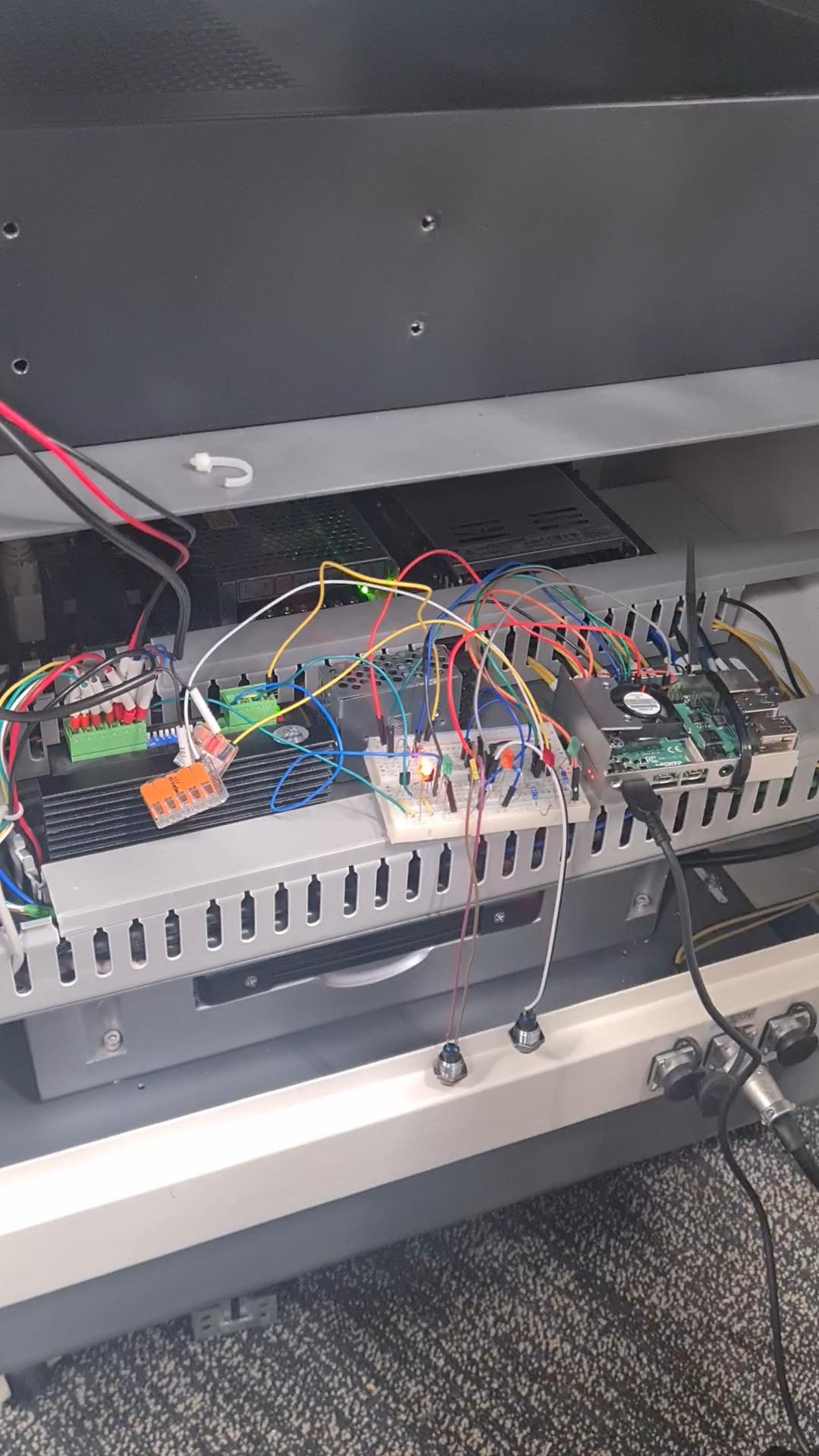

Hardware Setup:

- Raspberry Pi Model 4 4GB

- Oree R-t model laser

- Step Motor: 57CM22X

- Microstep Drive: DM542

- Controller with display: MC-24MR-4MT-500-FX-A

- Bottom and top sensors: TL-Q5MC1-Z

Raspberry Pi Contact Board:

To interface the Raspberry Pi with the Microstep Drive DM542 and incorporate buttons and LEDs for control and feedback, a custom contact board was created. The contact board consists of the following components:

Transistors Resistors Buttons LEDs This contact board facilitates the control and monitoring of the stepper motor and provides visual feedback through LEDs. It is responsible for translating signals between the Raspberry Pi GPIO pins and the connected components, enabling seamless integration into the overall system.

Software Setup:

Programming Language: Python Libraries/Frameworks: RPi.GPIO, time

Testing and Validation:

Extensive testing was conducted to ensure the accuracy and reliability of the height adjustment process. Commands were implemented to adjust the height for different locations, and the system demonstrated precise control, achieving adjustments accurate to within a tenth of a millimeter.

Challenges and Solutions:

Challenges encountered during development:

Integrating the Raspberry Pi with the Microstep Drive DM542. Ensuring accurate height adjustments based on database information. Solutions:

Using Python for GPIO control on the Raspberry Pi. Implementing specific wiring configurations for proper communication with the Microstep Drive DM542.

Code Explanation:

import RPi.GPIO as GPIO #Import necessary libraries import time GPIO.setmode(GPIO.BCM) #Set GPIO mode class Arm:

def __init__(self):

# Initialize GPIO pins and variables

self.settings()

self.sensor_down = False

self.sensor_up = False

self.buttonUp = False

self.buttonDown = False

self.actHeight = -1

self.check_read_sensors()

self.numberOfSteps = 0

# Function to initialize GPIO settings

def settings(self):

# Define GPIO pins for motor control, sensors, and buttons

self.motor_direction_pin = 27

self.motor_step_pin = 22

self.sensor_down_pin = 23

self.buttonUpPin = 25

self.buttonDownPin = 6

self.sensor_up_pin = 24

self.delay = 0.000003 # Adjust this delay for motor speed

self.pulses_per_rev = 5000 # Set pulses per revolution

# Setup GPIO pins

GPIO.setup(self.motor_direction_pin, GPIO.OUT)

GPIO.setup(self.motor_step_pin, GPIO.OUT)

GPIO.setup(self.sensor_down_pin, GPIO.IN, pull_up_down=GPIO.PUD_DOWN)

GPIO.setup(self.sensor_up_pin, GPIO.IN, pull_up_down=GPIO.PUD_DOWN)

GPIO.setup(self.buttonUpPin, GPIO.IN, pull_up_down=GPIO.PUD_UP)

GPIO.setup(self.buttonDownPin, GPIO.IN, pull_up_down=GPIO.PUD_UP)

# Function to perform a single step

def step_once(self):

self.numberOfSteps += 1

GPIO.output(self.motor_step_pin, True)

time.sleep(self.delay)

GPIO.output(self.motor_step_pin, False)

time.sleep(self.delay)

# Function to step the motor forward

def step_forward(self):

GPIO.output(self.motor_direction_pin, True)

self.step_once()

self.actHeight += 0.0008

# Function to step the motor in reverse

def step_reverse(self):

GPIO.output(self.motor_direction_pin, False)

self.step_once()

self.actHeight -= 0.0008

# Function to stop the motor

def stopMotor(self):

GPIO.output(self.motor_step_pin, False)

# Function to read sensor states

def check_read_sensors(self):

self.sensor_down = not GPIO.input(self.sensor_down_pin)

self.sensor_up = not GPIO.input(self.sensor_up_pin)

self.buttonUp = not GPIO.input(self.buttonUpPin)

self.buttonDown = not GPIO.input(self.buttonDownPin)

# Main function to start height adjustment

def start(self):

while True:

self.check_read_sensors()

if self.sensor_down and self.buttonDown:

self.stopMotor()

print('Hit bottom')

continue

if self.sensor_up and self.buttonUp:

self.stopMotor()

print('Hit top')

continue

if self.buttonUp and self.buttonDown:

self.stopMotor()

print('Both Sensors')

break

if self.buttonUp:

self.step_forward()

print('Forward')

continue

if self.buttonDown:

self.step_reverse()

print('Backward')

continue

self.stopMotor()

GPIO.cleanup()

# Function to find the bottom position

def findBottom(self):

while not self.sensor_down:

self.check_read_sensors()

self.step_reverse()

self.actHeight = 143

self.numberOfSteps = 0

# Function to move to a specified height

def goto(self, height):

self.check_read_sensors()

if self.actHeight <= height:

while round(self.actHeight,2) != round(height,2) and not self.sensor_up:

self.step_forward()

self.check_read_sensors()

else:

while round(self.actHeight,2) != round(height,2) and not self.sensor_down:

self.step_reverse()

self.check_read_sensors()

- Main function

if __name__ == "__main__":

print("Program has started")

a = Arm()

a.findBottom()

print('I am at 0 cm')

time.sleep(4)

print('Going up to 480 mm')

a.goto(480)

print('I am at 480 mm')

time.sleep(4)

print('Going up to 200 mm')

a.goto(200)

print('I am at 200 mm')

time.sleep(4)

print('Going up to 0 mm')

a.goto(0)

print('Stopped at 143 mm due to height limit')

GPIO.cleanup()

Conclusion:

The RPI Step Motor Controller project successfully achieves the goal of automating the process of controlling the height of the Oree R-t model laser arm. With further improvements and enhancements, it can effectively contribute to the automation of the laser marking process in production.